The Emperor’s Chair – ICSB Spotlight on Japan

Sep 26, 2018

ICSB’s – Asia Council for Small Business (ACSB) hosted its 6th regional conference in Tokyo in September 2018. The title of the conference was New Development of Small Business Policy and Management: Toward an Evidence-Based Policy Making for SMEs. ICSB Japan (JICSB) welcomed the world in Tokyo with a cutting-edge conference that blended research, policy, and practices. The organizer Dr. Hiroyuki Okamuro, Conference Chair opened the conference with a warm welcome to all local and international delegates.

Itsutomo Mitsui JICSB past president, Robert Lai, ICSB immediate past president, Hermawan Kartajaya, ACSB President, Indonesia, Ki-Chan Kim, ICSB past president, Vicki Stylianou, ICSB SVP of Development, and Ayman Tarabishy, ICSB Executive Director attended the conference with various Asia affiliate presidents and board members. A copy of the program can be found here:

The continuation of this article showcases on a remarkable SME that ICSB will highlight.

History of SMEs and Manufacturing in Japan:

Tokyo’s postwar economic history, especially the 1950s and early 1960s, in the area of SMEs and manufacturing can be described as unplanned and rapid organic growth.

A key area in Tokyo to capture the manufacturing small and medium-sized enterprises development is known as Sumida ward. Paul Waley’s article on “distinctive patterns of industrial urbanization in modern Tokyo ca. 1880-1930” is a great place to learn more about the history of this part of Tokyo.

The development on the Sumida River’s eastern bank stretches back to the Edo period when Fukagawa (today’s Koto Ward) was the site of many of the feudal lords’ warehouses. The Sumida ward location promoted “pioneering industrial facilities” on strategic sites. These large model factories were an attempt by the Meiji administration to transfer and diffuse Western technology in Japan. Sumida Ward relied heavily on rivers and canals for its infrastructural needs.

What is of high interest in Sumida that there was no industrial planning to speak of, and no zoning regulations governing the spatial growth of industrial districts. When the first land use regulations were enacted in 1919 with the City Planning Act, they reflected the status quo rather than provided the government with a strong tool to affect the economic structure of the city.

Sumida starting in the 1990s experienced a rapid decline due to a changing global climate and the Asian financial crisis. Data shows 30-40 percent of small manufacturing firms in Sumida closed. From a vibrant ward to abandoned warehouses seemed inevitable.

New Breed of Small Manufacturing Firm Emerges from the Ruins in Sumida

Yes, the title is accurate as this new breed of small manufacturing firm was created from a devasting fire to an existing factory in 2002. The owner, which, we will present shortly re-built the company from the ashes. The firm in simple terms, an old-school manufacturing firm but re-invented to meet today’s global challenges. Garage Sumida is an innovative hardware incubation facility, which is located inside an advanced metal processing factory Hamano Products. The company builds hardware products from design to prototype to commercial mass production. Their core strengths lie in rapid execution combined with extreme quality. They have over 50 years of technically complex manufacturing experience bringing product vision a reality.

Yes, the title is accurate as this new breed of small manufacturing firm was created from a devasting fire to an existing factory in 2002. The owner, which, we will present shortly re-built the company from the ashes. The firm in simple terms, an old-school manufacturing firm but re-invented to meet today’s global challenges. Garage Sumida is an innovative hardware incubation facility, which is located inside an advanced metal processing factory Hamano Products. The company builds hardware products from design to prototype to commercial mass production. Their core strengths lie in rapid execution combined with extreme quality. They have over 50 years of technically complex manufacturing experience bringing product vision a reality.

Imagine a district in your city where you have 1000-2000-3000 or even 10,000 small manufacturing hardware firms doing design, rapid prototyping, manufacturing and even exporting. The rules of the game are changing in Japan and the world better pay attention.

Introducing Mr. Keichi Hamano, CEO of Garage Sumida, an entrepreneur, a Humane Entrepreneur, and a simple visionary. Imagine at 2 a.m. you awaken with the news that your only source of income is destroyed by a fire! What would you do? He did what any decent human being would do, make sure everyone is first safe, then figure out what is next. For him, what is next is four days of manic search trying to identify a new temporary location for his factory. Sumida Ward has history, has culture, and a heart. The story as shared with ICSB that Mr. Hamano search led him to a shut-down factory that an elderly woman owned after her husband passed away. We were told he knocked at her door late in the evening asking if he can rent it. The elderly women, seeing the physical state of Mr. Hamano, was more concerned about his well being then his request. She asked him to sit in the kitchen so she can make him miso soup. The quote or something close to it was “Its no good for anyone if you are not strong or well enough, so, you need to eat.” In the end, the elderly women rented the space to him and Sumida neighbors assisted with the reconstruction.

Old School meets New School

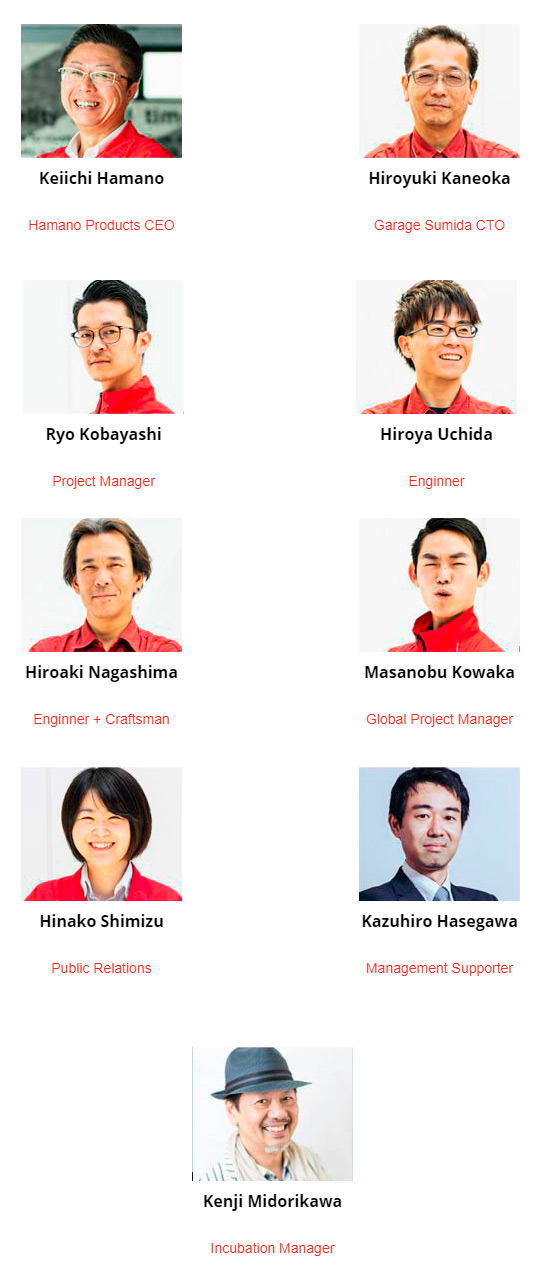

In our visit to the site, what was striking is how the manufacturing plant was designed. It was a mashup of the latest manufacturing machines, tools, toys, and gadgets and next to it old-school machines, paper, pen, hammer, nails, and rulers. Atoms and Bits co-existed in harmony and what was created was magic. This was not by accident, as the team behind Garage Sumida were philosophers, designers, students, blue-collar, white-collar, entrepreneurs, and dreamers coalescing around ideas. From an idea to a design to a prototype to let us manufacture it and sell it. Garage Sumida now works with firms from around the world. The Garage Sumida team below:

Team

Our team consists of skilled caftsman/enginner and project manager who supports from the idea phase to prototype and lastly, to product for market phase. You can also get advice from mentros including entrepreneurs and management supporter.

Keiichi Hamano

Hamano Products CEO

Hiroya Uchida

Enginner

Hinako Shimizu

Public Relations

Hiroyuki Kaneoka

Garage Sumida CTO

Hiroaki Nagashima

Enginner + Craftsman

Kazuhiro Hasegawa

Management Supporter

Ryo Kobayashi

Project Manager

Masanobu Kowaka

Global Project Manager

Kenji Midorikawa

Incubation Manager

The Emperor’s Chair

As we were visiting the various SMEs in Tokyo, the tour bus operator in his remarks stated that the Emperor of Japan, Emperor Akihito, visited an SME in Sumida in June of 2018 because of its innovative business model. This remarkable piece of information has a very symbolic and powerful message. Why would an Emperor visit a small manufacturing firm like Garage Sumida? The answer, after our visit, is obvious. The future of manufacturing in Japan will be based on SMEs like Garage Sumida.

Mr. Keichi Hamano, welcomes ICSB members from around the world to come to visit him, even sit on the same chair the Emperor sat in. More importantly, he welcomes all SMEs that want to change the world.

Article written by:

Dr. Ayman Tarabishy

ICSB Executive Director

Contribution from:

Vicki Stylianou, ICSB SVP of Development